pickle and passivate stainless steel

It has become a symbol of trust for most of the stainless steel industry today. Plum jam recipe without pectin.

What Is Passivation How Does Stainless Passivation Work

Read about pickle and passivate.

. In stainless steel the passivation process uses nitric acid or citric acid to remove free iron from the surface. It provides a passive surface immediately on rinsing hence you pickle and get a passive surface. Pickling and passivation are often used together to remove contaminates and oxidation improving corrosion resistance and extending the life and overall value of stainless steel components.

How to Pickle and Passivate Stainless Steel. If stainless parts are contaminated with grease or oil then a cleaning operation prior to acid treatment should be carried out. While chemical Passivation is intended to remove free iron and surface contaminates it is ineffective at removing existing oxidation weld oxides scale.

The 316 stainless steel has better pitting corrosion resistance than either the 303 or 304 stainless steel through addition of about 2-3 molybdenum. The chemical treatment leads to a protective oxide layer that is less likely to chemically react with air and cause corrosion. Allegheny Surface Technology uses pickling solutions containing nitric and hydrofluoric acids to remove weld scale and underlying chromium-depleted layers of a metallic surface in order to restore the corrosion resistance of stainless steel.

Passivation is a widely-used metal finishing process to prevent corrosion. Because the treated parts can be fully immersed in pickling and passivation solution the surface reaction is complete and the passivation film is dense and uniform. Ad Stainless Steel Passivation Services For Rust Prevention.

Both pickling and passivation are widely used for stainless steel products. Pickling and passivation are two forms of chemical metal finishing that provide protective properties to metal especially against rust. How to apply video of pickling and passivation chemical on stainless steel for clean and shining look.

Stainless steel pipeline elbow and small parts are most suitable for this method and the treatment effect is the best. Pickling is the removal of a thin layer of metal from the surface of the. Unlike pickling the passivation process does not remove any metal.

Ad Providing Customers With The Best Service Unsurpassed Quality Superior Metal Finishing. Can you pickle stainless steel. Pickling and passivation are both acid treatments and neither will remove grease or oil.

1 Complete the welding pressure release and non-destructive testing of pickling and passivation pipelines. SURFACE INNOVATORS LLP has been serving the stainless steel industry with their chemicals for pickling and passivation of stainless steel for over two decades. On-Site Services Services Available.

There are a few different methods for passivating stainless steel including chemical baths as well as brush-on and spray-on applications. To scale new heights in surface finishing on stainless steel with the core competencies of the organization to become a global leader in. The corrosion resistance of stainless steel is led by high content of chromium for example 316LWCr16001800.

2 According to the process requirements the pipeline to be pickled and passivated must be checked and qualified. Ad No Size Or Weight Limits. Pickling and Passivation are chemical treatments applied to the surface of stainless steel to remove contaminants and assist the formation of a continuous chromium-oxide passive film.

3 Prepare the cleaning package and cleaning tracking table for the. Combinations of degreasing cleaning pickling and passivation treatments may be necessary to fully prepare machined or fabricated stainless steel surfaces for their intended service conditions. Instead the surface of the stainless steel is treated with an oxidizing acid to dissolve carbon steel sulfide inclusions and remove iron and other surface contaminants from the stainless.

Call Request A Quote Now. The first involves submerging the item in a 10 by weight citric acid. Some acidic chemicals are used over the stainless steel to create a passive layer or to remove contaminants.

Pickling and passivation treatments may be necessaryto fullyprepare machined or fabricated stainless steel surfaces for their intended service conditions. 31 Preparations before pickling and passivation. Pickling is a pre-passivation process of treating stainless steel parts with an acid solution typically hydrochloric or sulfuric acid which can remove oxide scale and heat tint while dissolving steel flecks embedded in the part.

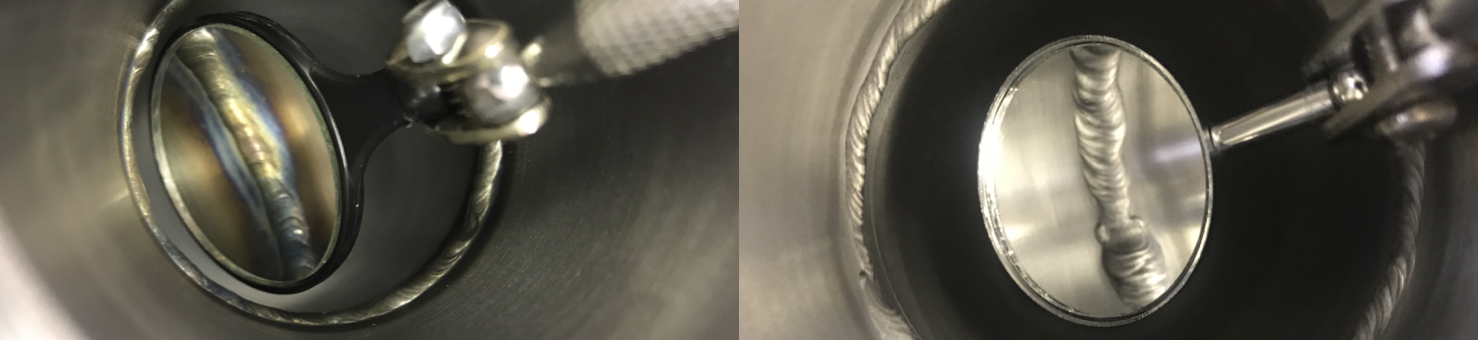

For types 304 and 316 whose chromium content is typically between 15 and 23 percent there are two common types of acid baths. Does 316 stainless steel need to be passivated. PICKLING AND PASSIVATING STAINLESS STEEL Light scaling left on weld.

PASSIVATION The treatment of the surface of stainless steel often with acid solutions or gels to remove contaminants and promote the formation of the passive film on a surface that was freshly created eg. Nitric acidcitric acid passivation. Therefore the ability to be resistant to corrosion of stainless steel is attributed to the its capability that it can form a corrosion resistant oxide layer when contacting with air.

Passivation is a process that is separate from pickling which can be performed on its own or after pickling. If the fabrication is dirty it may be necessary to use a detergent or alkaline clean before pickling or. Or in other terms pickling and passivation are the name of the two processes where the metal is submerged in a bathing liquid that removes imperfections and rust from the surface of metal.

Principle of Pickling and Passivating. Pickling and passivation both are chemical treatment processes used for surface treatment of stainless steel after welding or exposure to high temperature to clean. Pickling is one of several possible pretreatment steps in other processing such as passivation or.

If stainless parts are contaminated with grease or oil then a cleaning operation prior to acid treatment should be carried out. Through grinding machining or mechanical damage. However even with the addition of the molybdenum the 316 would have the same need for passivation as the 303304.

Pickling and Passivation are chemical processes used in the metal industry to protect metals from corrosion. Congruent Electropolishing Passivating Pickling Lines.

What Is Passivation How Does Stainless Passivation Work

Pickling And Passivating Of Metals Vecom Group

New Pickling And Passivation Baths Cb Stainlesscb Stainless

Inox Passivation Pickling Passivation Astm Asme

Why Stainless Steel Pipe Needed Acid Pickling And Passivation World Iron Steel

Pickling And Passivation Of Stainless Steel Pipes

Pickling And Passivating Of Metals Vecom Group

How To Pickle And Passivate Stainless Steel The Home Brewing Guide To Stainless

Passivazione Dell Acciaio Inossidabile Nitty Gritty

Pickling And Passivation Of Stainless Steel Welds Joints

Pickling And Passivating Stainless Steel Safe Food Factory

Pickling Passivation Services On Site Shop Astro Pak

Passivating Stainless Steel Aluminum Clinton Aluminum

Stainless Steel Spray Pickling Passivation Services In Ohio

Stainless Steel Pickling And Passivation Westchem Technologies Inc

Pickling And Passivation On Stainless Steel Youtube

Stainless Steel Passivation Pickling Descaling The Super Blog

Stainless Steel Passivation For Enhanced Durability And Versatility